How MEPF Scan to BIM Services Streamline Mechanical, HVAC, Electrical, and Plumbing Design

When an existing building is undergoing renovation or retrofit, it often starts with the most fundamental and essential question of “What’s actually behind this wall and above this ceiling?” Unfortunately, most projects using as-built documentation are outdated or sometimes not available at all, resulting in unforeseen costs, design inconsistencies, schedule delays, and significant rework, especially for reference to MEPF (Mechanical, Electrical, Plumbing, Fire Protection) complexities. This is where technologies like 3D laser scanning come into play. Using 3D laser scanners in combination with Scan to BIM workflows, project teams are now able to capture and document the existing conditions accurately and produce intelligent 3D Models.

We will discuss how MEPF Scan to BIM Modeling Services in the USA produces an accurate digital twin, allowing for efficient design, coordination, and execution of the mechanical, HVAC, electrical, and plumbing systems.

Understanding Scan to BIM in MEPF

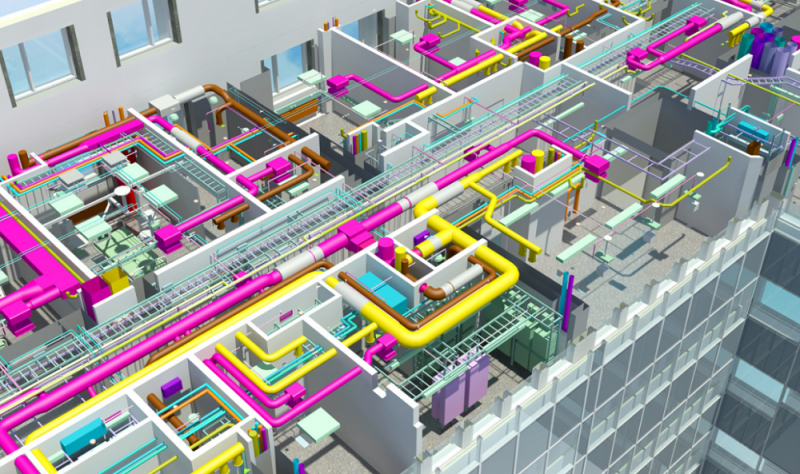

MEPF Scan to BIM Modeling Services refers to the transformation of reality captured data obtained from 3D laser scanning into intelligent Building Information Models specified for Mechanical, Electrical, Plumbing, and Fire Protection systems.

The Scan to BIM workflow for the MEPF system begins by scanning an existing facility to create a high-quality point cloud, which is then converted to accurate BIM models, specifically representing the ducts, pipes, conduits, equipment, and other components of the MEPF system. Engineers, Contractors, and Facilities Managers use this approach to get a clear understanding of existing conditions, identify potential clashes, and make informed design decisions. Point cloud to BIM creates the link between the physical space and the digital model for the purpose of coordination and optimizing project delivery.

Challenges in Conventional MEPF Design

The design and installation of MEPF systems have traditionally been complex, and conventional methods often do not meet the intricacies that the project demands.

Common issues include:

- Insufficient As-Built Documentation: Drawings are often outdated or missing, making it difficult to assess existing conditions and raise design risk.

- Clash Coordination: Ductwork, pipe, and conduits often clash with structural beams or interfere with other systems, resulting in coordination conflicts in construction.

- Slow Survey Processes: Conducting manual measurements in the field is a laborious process that often still results in human eye errors, leading to additional redesign iterations.

- Expensive Change Orders: Late discovery of design mistakes leads to expensive rework, waste of material, and disruption of schedules.

- Poor Facility Management: Without reliable digital records, facility management becomes difficult, directly impacting the long-term performance of the building.

Each of these limitations helps explain why many MEPF professionals are looking to streamline their design efforts, coordination processes, and long-term management of buildings, using a common process of Scan to BIM.

How Scan to BIM Services Streamlines MEPF Workflows

MEPF systems are essential for building design, and the installation process requires a high level of accuracy and coordination. Scan to BIM can help convert the raw point cloud data into intelligent 3D models that streamline the process of designing and analyzing MEPF components and fully integrating them into the design.

Here is how it helps for each discipline:

Mechanical Systems

Mechanical equipment, including chillers, pumps, and boilers, is essential for the operation of a building. Scan to BIM services allow modeling of components accurately and with precision, down to the exact dimensions and locations. This will help develop an effective layout of the equipment and optimize the equipment spatially, which is vital when dealing with crowded plant rooms. The model also helps with energy efficiency and allows engineers to analyze performance and tweak operations to reduce operational costs long-term.

HVAC Systems

HVAC systems require coordination across floors and spaces. Scan to BIM allows accurate duct and ventilation modeling, which minimizes conflicts with structural or architectural elements. Engineers can even visualize how airflow moves through the BIM environment to optimize comfort levels and maximize system operations. The model also allows engineers to ensure compliance with building codes, ventilation requirements, and sustainability measures.

Electrical Systems

Electrical design can also be problematic because of the number of conduits, cable trays, and fixtures in one space. By using Scan to BIM, electrical systems can be exactly located in relation to the other disciplines, which minimizes conflicts with plumbing and HVAC. The model can further assist engineers in planning electric loads and the capacity of the electrical system for future expansions.

Plumbing & Fire Protection

It is essential to have efficient and safe plumbing and fire protection systems. Scan to BIM guarantees that all routed piping is modeled in its proper spatial context to eliminate potential clashes with other services. The modeling executed via Scan to BIM allows for prefabrication of associated pipe assemblies, as well as increased installation efficiency while reducing construction waste. Furthermore, modeling a fire protection system, in accordance with the established safety codes and permitting practices, ensures the safety of occupants and infrastructure.

By improving and utilizing these workflows, Scan to BIM leads to clarity, coordination, and efficiency in MEPF design and execution.

Key Advantages of MEPF Scan to BIM Services

Implementing MEPF Scan to BIM presents identifiable benefits at all stages of the project lifecycle.

Significant benefits consist of:

- Clash Detection & Coordination: The incorporation of all MEPF systems into one BIM model enables early identification of potential clashes with ducts, pipes, conduits, or structural elements and reduces high-cost issues in the field.

- Accelerated Project Delivery: Automated data capture and accurate modeling drastically decrease survey time and design cycles to keep projects on schedule.

- Cost Reduction: The reduction of re-work, change orders, and material waste during the design, construction, and operations results in substantial overall cost savings.

- Enhanced Collaboration: A unified 3D model enables architects, engineers, contractors, and facility managers to share the same information, facilitating better collaboration and more informed decision making.

- Facility Management: The as-built BIM model serves as a digital twin and provides reliable information for future maintenance, renovations, and upgrades.

These benefits together validate the use of Scan to BIM as an effective strategy to improve MEPF projects and sustain the building’s performance over time.

Applications of MEPF Scan to BIM Services Across Project Types

MEPF Scan to BIM services are flexible and can be used on any type of building construction project.

- Renovating Old Buildings: Useful for retrofit or renovations where original drawings are lost or the drawings are outdated, providing accurate as-built documentation.

- Healthcare and Commercial Facilities: Critical in coordinating complex MEPF systems for hospitals, malls, and offices.

- Industrial Plants: Effectively models large systems for efficient layouts and safe working environments on very large systems of heavy equipment, piping, and utilities.

- Infrastructure Projects: Airports, rail systems, and data centers can benefit from the detailed modeling to support larger, complex systems for MEPF system coordination.

Scan to BIM provides the clarity to support the coordination of MEPF systems, whether for a historic building or high-tech facility.

Conclusion

All in all, MEPF Scan to BIM services have helped change the way mechanical, HVAC, electrical, and plumbing systems are designed, managed, and maintained. By converting reality captured data to accurate 3D models, project teams can detect clashes early, reduce rework, and increase project timeline. MEPF Scan to BIM services help achieve accurate integrated systems and long-term efficiency for renovations, commercial buildings, industrial plants, and large infrastructure. MEPF Scan to BIM Modeling Services in the USA provides architects, engineers, and facility managers to develop digital twins, reduce workflow, promote collaboration, and sustainably and affordably develop future-ready building solutions.